Toyota has pledged to cut the processes that slow down innovation in half; check out some of the advancements helping it achieve that.

Long accused of being a latecomer to the electric vehicle game, Toyota has been busy lately telling the world how it’s going to reinvent the way it produces cars in order to become an EV powerhouse. And today we know more about how the world’s biggest automaker plans to get there.

Under new CEO Koji Sato, Toyota aims to launch 10 new EVs by 2026 and targets annual sales of 1.5 million EVs in 2026 and 3.5 million in 2030. (Additionally, Lexus aims to go fully electric in North America by 2030 and then globally by 2035.) This is a very ambitious plan, as Toyota sold only 24,400 battery-electric vehicles worldwide last year, but let’s not forget we’re talking about an industrial giant that sold 10.5 million vehicles in 2022.

Much of this relies on Toyota’s next-generation manufacturing processes, which the company previewed last month in Japan at three of its plants. Now, the automaker has released more details about how the new EV manufacturing breakthroughs will help it churn out electric vehicles and batteries more quickly at much lower costs.

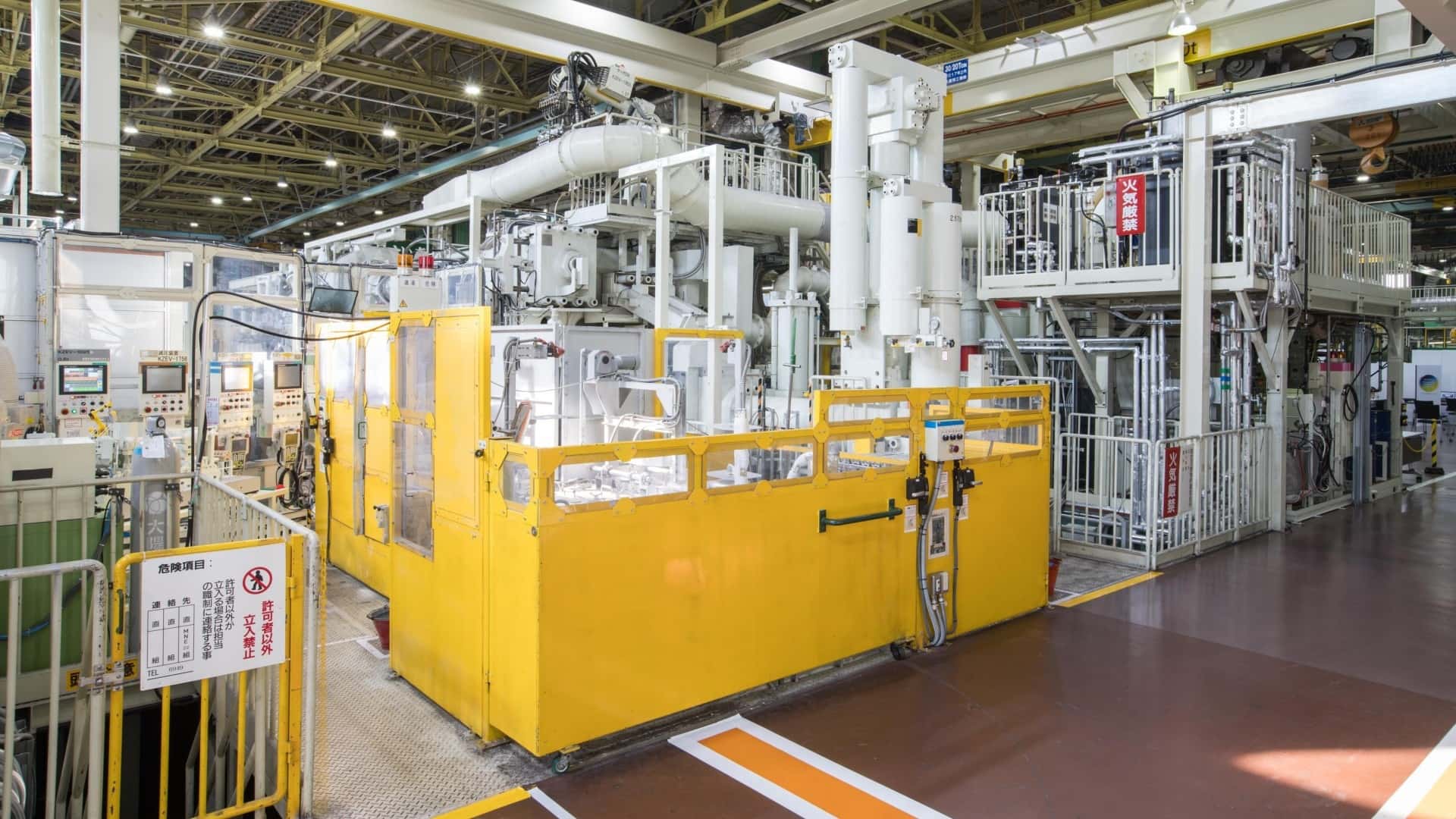

Last month’s Monozokuri (Production) Workshop showcased manufacturing advancements including giga casting, automated cars that drive themselves down the line, splitting cars into three parts vertically to speed up assembly, and the next-generation battery assembly line.

Gallery: Toyota Next-Gen EV Production Line

At the event, Toyota promised to cut the processes that slow down innovation in half, which is a huge ambition. Toyota’s Chief Production Officer, Kazuaki Shingo, said the automaker would “halve processes using Toyota’s skills and digital and innovative technology, eliminate the barriers between development and production to provide new mobility quickly and work to resolve issues at the foundation of Monozukuri, such as factory carbon neutrality and logistics.”

This should help reduce production costs, something that’s currently crushing for most of the legacy automakers and an area where Tesla and the Chinese newcomers are way ahead. Let’s dive into how Toyota wants to catch up.

Next-Generation Battery Assembly Line

The Japanese automaker’s Teiho plant is getting ready for mass production of solid-state batteries, which are expected to become commercially available in its next-generation BEVs in 2027-2028. The new batteries are expected to increase the range to around 621 miles initially and reduce charging to where cars can go from 10% to 80% in 10 minutes.

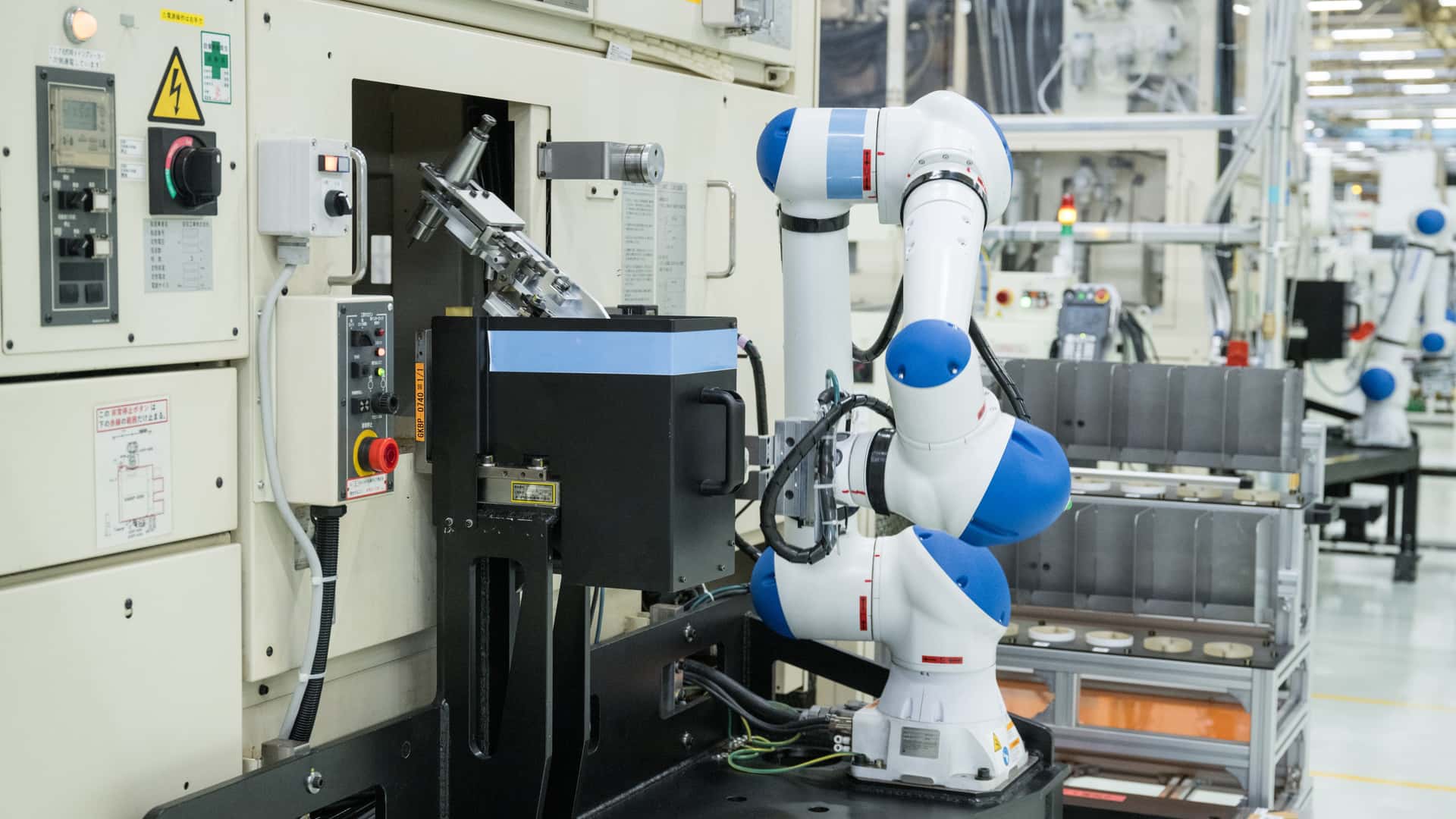

The plant will handle everything from “equipment design to assembly and installation,” Toyota says. One of the key technologies for mass production during the battery assembly process is high-speed, high-precision stacking that doesn’t damage the battery materials.

Prototype all-solid-state battery production line inside a temperature- and humidity-controlled room at Teiho plant

To address that, Toyota made it so the pallets that carry and receive batteries all move at the same speed. In addition, all pallets and machinery are equipped with mechanisms to prevent misalignment as the batteries are passed through.

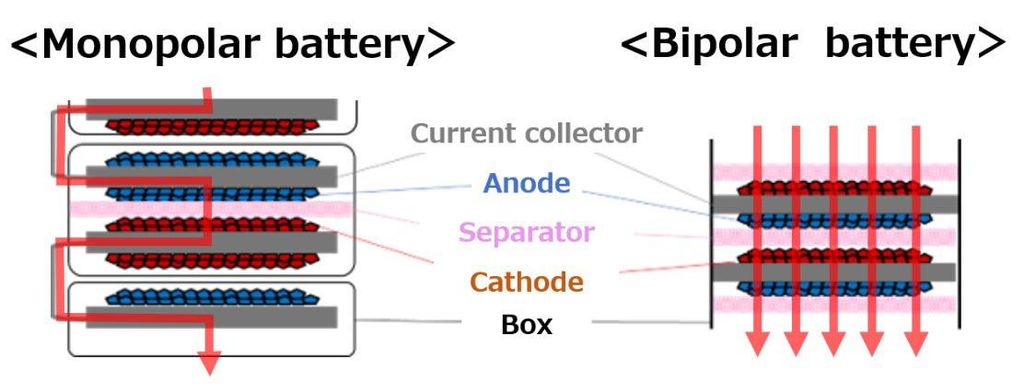

At the same time, Toyota plans to cut material costs by using lithium iron phosphate (LFP) for the cathode of the so-called popularization version of its next-generation battery, which will feature a supersized bipolar structure; normally, the cathode would be coated with rare metals such as nickel and cobalt.

To compensate for lower energy density and maintain battery capacity, the current collectors will have a thicker coating of LFP, using the space gained through employing a bipolar structure with fewer components.

Mind you, to make these batteries a reality, Toyota must overcome several challenges: applying the material evenly, doing so at high speeds, simultaneously sealing all the cells, and doing this on large surface areas – i.e. on batteries big enough to power an automobile.

The automaker plans to tackle these challenges by tapping into its 26-year experience in battery production technologies for its hybrids, its bipolar nickel-metal hydride battery technology and expertise, the precision coating used for FCEVs, and various digital technologies. That’s been a sticking point for many critics: where is the company that gave the world hybrids at scale on fully electric cars?

Self-Propelled Assembly Lines

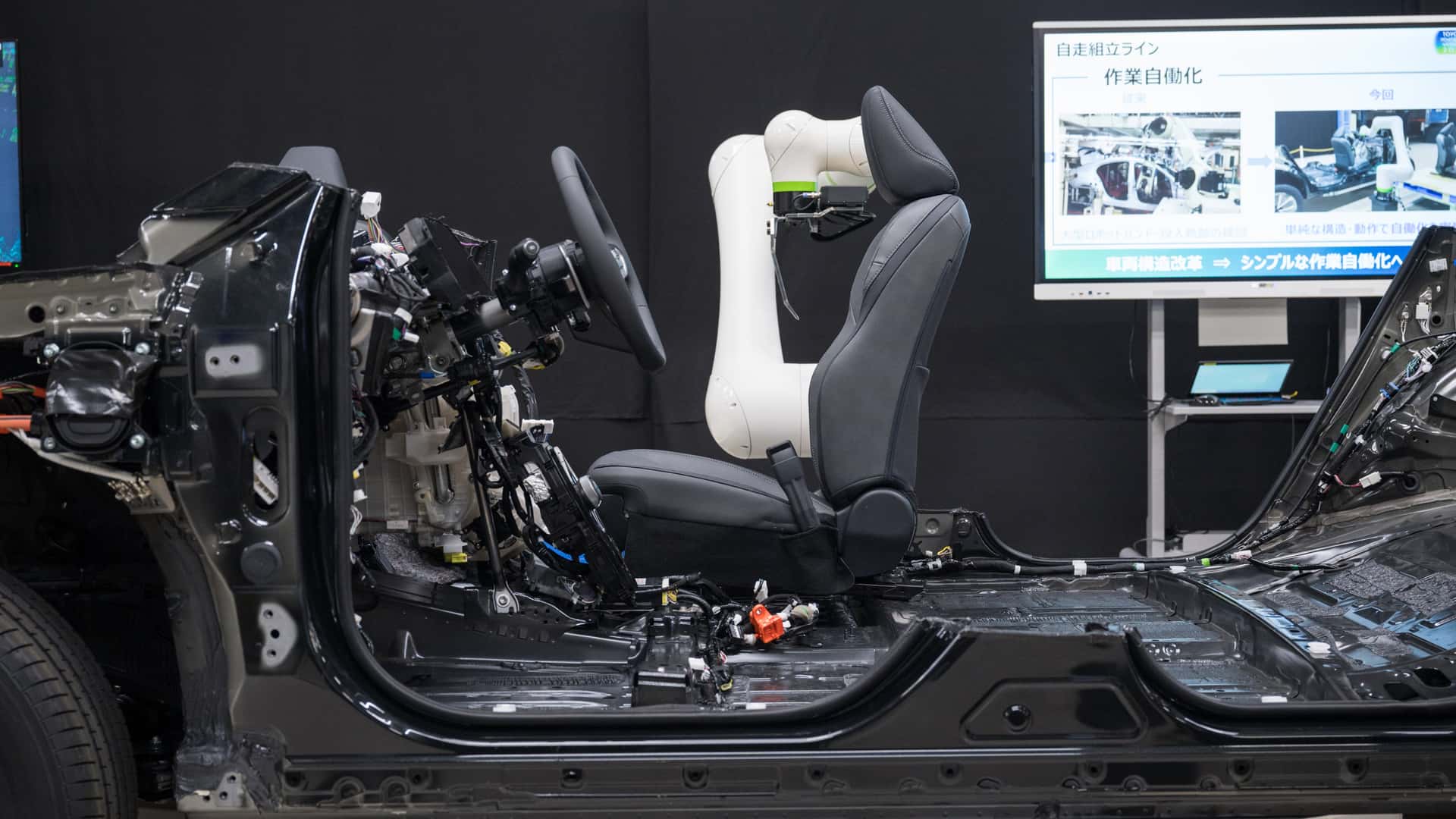

As previewed last month, Toyota has also taken an entirely new approach as to how vehicles are assembled. Instead of combining the chassis and body in traditional fashion, the automaker will now split the car into three parts vertically: a front section, a middle section, and a rear section.

The Motomachi plant, which is where the pilot for this new assembly line is located, will divide future Toyota architectures – including the underbody, the front frame, and the cabin and trunk floor – into three sections, each fitted with its own parts.

This will present several advantages for workers, who will no longer need to climb inside a vehicle during assembly, speeding up the process. Furthermore, seats and other components will be mounted before the roof and side panels are attached, which will simplify the designs and operations of robots and other equipment.

Why is it called a self-propelled assembly line, though? It’s because the cars being assembled will move under their own power at very low speed. The sensors and vehicle control technology developed for autonomous driving will be used to govern how fast the assembly line moves and operates. Cameras throughout the plant track the cars, keeping them moving along the set route at 0.22 mph (0.36 kph).

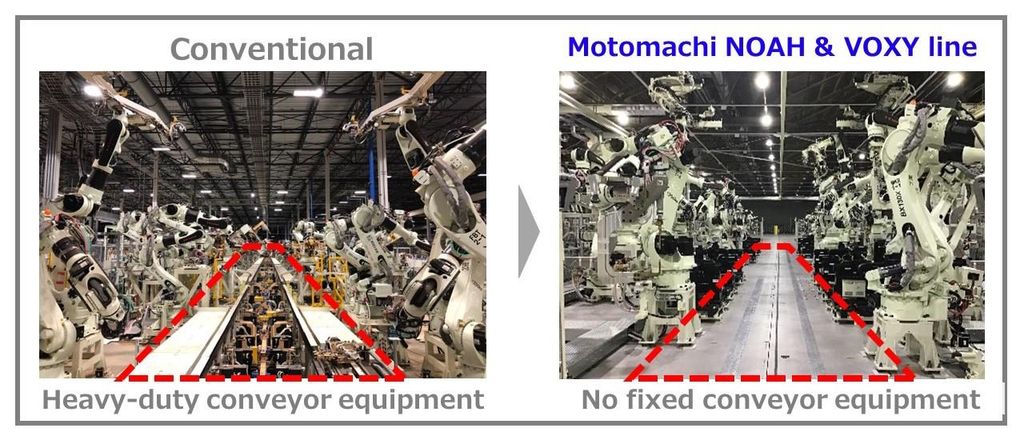

This solution has two main advantages: it eliminates the need for conveyor belts, saving billions of yen in capital investment in the process, and it drastically shortens the years-long lead times for switching to new models. Toyota has already trialed a simplified line concept using unmanned transport robots as part of the welding process for the Noah and Voxy models.

Giga Casting

Leading the charge on Toyota’s future giga casting operation is the company’s Myochi plant. Brought to the mainstream by Tesla, giga casting, which is the use of large, single-piece castings for major structural components of a vehicle, will make a huge difference in the manufacturing process of Toyota’s future EVs.

As a very evocative example, the rear section of the Toyota bZ4X is currently made from 86 individual castings, but in the future, the entire back end of the car will be made from one giant cast.

The process consists of injecting molten aluminum alloy into a mold at high speed and pressure. In a matter of seconds, the material is cooled from 700°C to 250°C (1292-482°F) and solidified. Then, the mold is opened to remove the integrated cast part.

Equipment for giga cast prototyping at Toyota’s Myochi plant

Giga casting molds weigh up to 100 tons, requiring large cranes to move them and taking more than a day for changeovers. To reduce downtime, Toyota is dividing its molds into two types: general-purpose molds and specialty molds.

The former will remain mounted on the machinery while the latter, whose shapes differ by car model, will detach themselves automatically from the general-purpose molds. As a result, downtime will be cut from 24 hours to just 20 minutes.

Furthermore, Toyota says it has digitized “artisan skills” to limit waste due to the expansion and contraction of the material, as well as reduce the likelihood of defects and the need for reworking.

Other manufacturing advancements that Toyota is working on implementing into mass production include expanding the use of digital technology and implementing vehicle handing robots to assist with transporting cars (see video below.)

Still, Toyota has a lot to prove on the EV front, and it can’t afford to waste time as Tesla eats into some of its sales in key markets and China’s electric automakers rise in power. But Toyota’s customers have been waiting for this news for a long time. Do you think Toyota can become an electric powerhouse too?

Source: Toyota Times

Comment!

Keyword: Here Are Three Radical Ways Toyota Is Reinventing Its EV Production